The Modern Ski

Ski Construction – Putting It Together

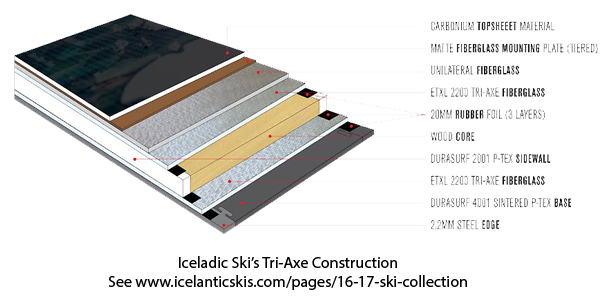

Better understanding of chemistry and fabrication technologies has created the ability to make complex materials very thin and bind them with other layers of material. This is reflected in modern skis which are universally sandwiches: thin layers of materials bonded together.

These layers offer manufacturers a wide set of materials to create a wide set of performance characteristics. Softer materials for powder skis, harder ones for front side skis.

| Name | Location | Description |

|---|---|---|

| Sandwich slices | Layers of your ski | The layers or slices that make up your ski |

| -Top Sheet | Top layer of ski | -A very thin protective layer -Graphics generally printed on this layer |

| -Composite layer(s) | Various layers, generally above and below the “core” | Composite materials (Aramid, Fiberglass, Titanal, etc.) generally used as wraps to create a ski’s torsional’s strength. |

| -Core | Middle of the ski (the “core”) | The core as the name implies is the center of the ski. Manufacturers use the core to create stiffness and flex patterns. |

| -Dampening Strips / Materials | Various layers | Rubber or other materials layered in strips or patterns to dampen ski vibrations |

| -Base | Bottom or base of ski | The sliding surface. This base material combined with wax creates the coefficient of friction |

| Sides & Tips | ||

| -Sidewalls | Edge of the ski above the metal edge. Can be a true sidewall, or a wrap. | Sidewall construction techniques help create torsional rigidity and protection for the skis top later. |

| -Edge | Bottom edge of ski | The metal edge that is skied on. |

With this information, a ski buyer can better analyze how a manufacturer constructs their ski. If you’re looking for carving skis, make sure the manufacturer is using materials (see Ski Construction Materials section) that support torsional stiffness. If you’re a bit older and want to minimize vibrations, see if the manufacturer is using dampening layers.

As always, Michale and I recommend that you always test or demo a ski before buying one. Regardless of how much you know about a ski, your skiing ability is key to the performance you’ll get from that ski. I’ve skied Michael’s carving skis which tend to be narrower, have minimal rockers, and a riser plate. I cannot get these skis on edge and hold them across varying terrain. I like my rockers and get little performance benefit from the riser plate. I’m just not good enough to ski his skis.

It should be noted that others might say that I could learn or grow into these skis. There may be truth to this. However, if you’re taking a GNASA, do this a season or two before your trip. Trying to grow into a ski on a GNASA is not recommended.

Elan Ski Manufacturing Examples